Have you ever walked into a store only to find the item you wanted was out of stock? Now multiply that frustration across multiple locations of the same business, and you’ll understand the challenges of multi-location inventory management.

For businesses with many locations, keeping track of stock isn’t simple. Just think about all the moving parts: Predicting what customers will buy, making sure each store has the right products, and keeping everyone happy. Too much stock ties up money and takes up space. Too little leads to empty shelves and disappointed shoppers. And moving products between stores? That’s another headache altogether.

The answer to these problems is good multi-store inventory management. This means being able to see how much stock is in each store at any time. It helps businesses track products, predict what they’ll need, and fix stock issues quickly. When done right, this approach has many benefits. Businesses can better guess what they’ll sell, put the right amount of stock in each store, and easily move items between locations.

In this article, we’ll explore practical ways to manage inventory across multiple stores. We’ll look at the unique challenges of having stores in different locations and show how Jovvie’s features can turn inventory management from a constant worry into a business strength!

Key challenges in managing inventory across multiple locations

Managing inventory across several locations comes with a set of challenges that can affect how well a business runs and how much money it makes. Let’s look at some of these issues:

- Communication gaps: When you have different warehouses, each might have its own way of doing things. This can lead to mix-ups in information, resulting in wrong stock counts, late orders, and unhappy customers.

- Inventory control issues: As you add more locations, keeping track of stock gets trickier. You might end up with too much in one place and not enough in another. This ties up money and space, making things less efficient.

- Order bottlenecks: If warehouses aren’t well-organized or don’t follow the same rules, it can slow down getting orders out, frustrating customers and costing more because of shipping delays.

- Tracking and visibility challenges: Without good tracking systems, it’s hard to know exactly what you have and where. This can lead to having too much or too little stock, both of which cost money. Good inventory software can help you see what’s happening across all your locations.

- Complex logistics management: Each location might need different shipping routes and supply strategies based on what local customers want. Coordinating all of this while making sure deliveries are on time adds another layer of difficulty to managing inventory across multiple locations.

Strategies for optimizing multi-location inventory management

1. Implement a centralized inventory management system

A centralized system gives you real-time visibility of stock levels across all locations, so you can see at a glance what’s available, where it is, and how fast it’s selling. With this information, you can make quicker, more informed decisions about restocking, transfers, and sales strategies.

2. Standardize processes and procedures across all locations

When every location follows the same rules, you reduce mistakes and improve consistency. It’s important to train your staff well so everyone’s on the same page. This way, whether you’re in Store A or Warehouse B, things work the same way.

3. Utilize data analytics and forecasting

Advanced analytics tools can crunch numbers from all your locations, considering factors like seasonality, promotions, and local trends. This helps you forecast demand more accurately for each location, ensuring you have the right products in the right places at the right time.

4. Implement a robust cycle counting program

Regular stock checks improve accuracy. Instead of big, disruptive annual counts, do smaller, more frequent ones. This keeps your inventory numbers up-to-date and reliable.

5. Optimize warehouse layouts and product placement

Design your warehouse layouts with efficiency in mind. Use data on picking frequency to place fast-moving items in easily accessible locations. Consider using zone picking or implementing a warehouse management system to guide staff to the most efficient picking routes. Also, take into account regional preferences when allocating stock – what sells quickly in one location might move slowly in another.

6. Leverage cross-docking and transfer strategies

Cross-docking involves moving products directly from receiving to shipping with minimal storage time. This can be particularly useful for high-demand items or pre-allocated stock. For slower-moving items, develop a system for easy transfers between locations. This might involve regular “milk runs” between stores or using excess space in delivery trucks for inter-store transfers.

7. Implement safety stock and reorder point strategies

Figure out how much extra stock each location needs to avoid running out. Set up automatic reorder points that change based on how long it takes to get new stock and how demand varies. This helps keep your inventory levels just right!

Leveraging technology: Essential features of multi-location inventory software

Managing inventory across multiple locations requires tools that go beyond basic software. Here are some key features that can help:

- Real-time updates keep all your locations in sync. When someone makes a change, it shows up everywhere instantly, ensuring your data remains accurate across all sites.

- A central dashboard shows you the big picture and lets you zoom in on specific locations. You can easily spot where you have too much or too little stock.

- Smart reordering systems learn from each location’s sales patterns. They help you avoid running out of popular items or having too many slow sellers.

- Predictive tools can guess what each location will need in the future. This helps you prepare your stock before demand hits.

- Transfer management helps you move stock between locations. The system suggests when and where to shift items to keep all sites well-stocked.

- Location-based allocation finds the best places to store and ship your products, saving time and money on shipping.

- Multi-channel integration connects your inventory system with your online store, physical shops, and other sales channels. Everything stays in sync, no matter where a sale happens.

- User permissions let you control who can see and change information at each location. This keeps your data secure and tracks who does what.

Jovvie POS: Streamlining inventory coordination across your stores

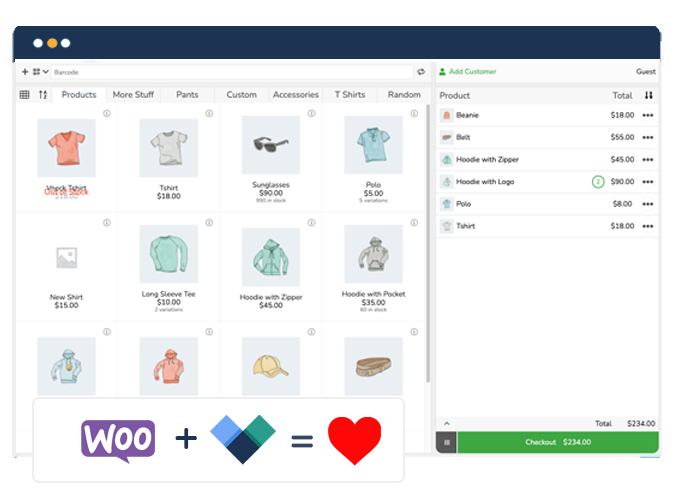

Jovvie by BizSwoop is a Point of Sale (POS) system that helps businesses manage inventory across multiple locations. It works effortlessly with WooCommerce, making it perfect for companies with both online and physical stores.

Real-time synchronization and centralized inventory control

One of Jovvie’s best features is its dynamic live inventory system. It keeps your stock levels up-to-date across all channels, preventing overselling even when customers shop online and in-store simultaneously. The system checks stock availability at key stages, ensuring accuracy.

Setting up Jovvie is straightforward, especially if you’re already using WooCommerce. It inherits many settings, saving you time and reducing compatibility issues. This is particularly helpful when expanding to new locations. Plus, if you want to extend Jovvie’s functionality, you can integrate it with other plugins and extensions like BizPrint for fulfilment document printing and Flow Notify for order notifications.

You have options with Jovvie – choose between cloud-based or self-hosted versions to fit your IT needs. And you’re not tied to one device; you manage your inventory from desktops, tablets, or smartphones, wherever you are.

Additionally, Jovvie provides a centralized dashboard in the WordPress admin panel. This means you can manage inventories for all your stores from one place, simplifying your multi-location operations.

Advanced analytics for data-driven inventory decisions

Jovvie doesn’t just track your inventory; it helps you understand it. You’ll find detailed reports right in your WooCommerce dashboard, showing product sales data and customer insights across all locations.

Need real-time inventory data? Jovvie gives you that instantly. This means you can make quick, informed decisions about stock transfers or reordering, keeping your inventory levels optimal across all stores.

The system also provides visibility into stock levels and sales performance across different channels. This feature helps you make smart decisions about inventory distribution and develop store-specific stocking strategies based on local demand patterns.

Benefits of effective multi-store inventory coordination

When you manage inventory across multiple stores effectively, you unlock a range of advanced benefits that can improve your business operations.

- Improved visibility across locations: A centralized inventory management system gives you real-time insights into stock levels, sales trends, and customer preferences across all your locations. This clear view lets you make informed decisions quickly, adapting to market demands as they change.

- Optimization of stock levels: With accurate demand forecasting and strategic inventory allocation, you can ensure that each location has the right products at the right time.

- Inventory transfers: When one store experiences higher demand for a particular product, you can quickly redistribute inventory from other locations to meet this need. Thanks to this flexibility, you can improve service levels and maximize the use of available resources across your network of stores.

- Cost savings through economies of scale: By consolidating purchasing decisions and leveraging bulk buying, you can negotiate better terms with suppliers, reducing overall procurement costs for your business.

- Improved collaboration among teams: A unified approach to inventory management encourages teams to share best practices, streamline processes, and work together towards common goals.

Transform your multi-store inventory management with Jovvie today

Managing inventory across multiple stores presents unique challenges, from maintaining accurate stock levels to optimizing inventory distribution. However, with the right tools, these challenges become opportunities for growth and efficiency.

That’s where Jovvie comes in. It’s designed specifically for businesses with multiple locations. Jovvie’s live inventory system keeps your stock levels up-to-date across all your stores in real time. No more accidental overselling or running out of stock unexpectedly. And Jovvie is flexible. Use it on tablets, computers, or smartphones – whatever works best for you and your team. You can manage inventory and process sales from anywhere in your stores.

Jovvie is also great at handling the complexities of multi-location operations. With its advanced features, you can set different prices and product availability for each store, transfer inventory between locations, and access detailed reports for each site. As a result, you can make smart, location-specific decisions based on actual needs and performance data.

Ready to take charge of your multi-store inventory? Give Jovvie a try and see the difference it can make!